Indian scientists develop new method for energy-efficient hydrogen production

Scientists have identified a new catalyst that can efficiently oxidize urea and pave the way for better production of green fuels while reducing energy demands for hydrogen production by urea-supported water splitting. Is. Recognizing the importance of hydrogen energy in reversing climate change, the scientific community is accelerating efforts to revolutionize the production of hydrogen, a key component in the clean energy landscape.

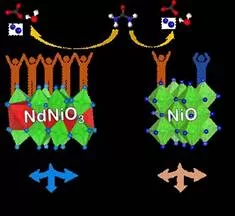

The electrolytic production of hydrogen at the cathode, despite being naturally clean and green, is hindered by the demand for energy expended in the process of oxygen formation at the anode (counter electrode). This process of oxygen formation is also known as other anodic Replacing them with processes such as the urea electro-oxidation reaction (UOR) provides a viable solution that has lower overall cell efficiencies.

Adding urea to water has been shown to reduce the energy demand for practical electrochemical hydrogen production by approximately 30%. This not only reduces the cost of hydrogen production from water by reducing electrical energy input but also assures recovery of urea from waste water along with energy production by converting urea into nitrogen, carbonate and water. Get.

Despite the potential benefits of this reaction, catalysts developed so far are not consistently sensitive to COX toxin (a co-product of UOR), hindering industry-scale implementation of this process. .

This research work, published in ACS Catalysis, a journal dedicated to publishing experimental and theoretical research on catalytic materials, can guide future studies aimed at increasing the number of NiOOH species and stabilizing these species on Ni3+-rich substrates . The goal is to achieve better performance with lower mass loading of active nickel (Ni) in the catalyst, which is an important step towards sustainable and efficient hydrogen production.